The team led by Professor In Soo-Il in the Department of Energy Engineering at DGIST has developed a high-efficiency photocatalyst capable of converting carbon dioxide (CO2), a major contributor to global warming, into the energy resource methane. The research team optimized the composition of nanoparticle co-catalysts and ruthenium doping to maximize the optical and electrical properties of the photocatalyst.

Simultaneously, they improved the methane conversion efficiency by enhancing CO2 adsorption through hydroxy surface treatment. The research team expects this technology to be applicable to carbon capture and utilization, making it possible to control the steadily increasing concentration of atmospheric CO2 while converting it into methane resources.

In 2022, the global CO2 concentration surpassed 420ppm, the highest level in 4.1 million years. Unprecedented increases in atmospheric CO2 concentrations have led to climate-related disasters worldwide, including 20 billion USD (approximately 25.4 trillion KRW) in economic losses due to droughts in Europe and record-breaking torrential rains on the Korean Peninsula.

To address this issue, the concentration of CO2, the cause of climate disasters, should be reduced. The World Economic Forum has identified “solar compounds” capable of converting CO2, a major contributor to global warming, into various fuels using solar energy as one of the top ten promising technologies of 2020.

Among solar compound technologies, photocatalysts that convert highly stable CO2 into fuels such as methane using only sunlight and photocatalysts through gas-phase reactions are drawing attention as key technologies for the future chemical industry, with the aim to reduce atmospheric CO2 and produce fuel simultaneously.

However, currently commercialized photocatalysts like P25 have limitations, such as a large bandgap that prevents the absorption of visible light and slow charge transfer. Several studies have attempted to solve these issues. However, challenges in achieving high-efficiency photocatalyst development have persisted due to inherent problems like low CO2 adsorption and conversion efficiency in gas-phase reactions.

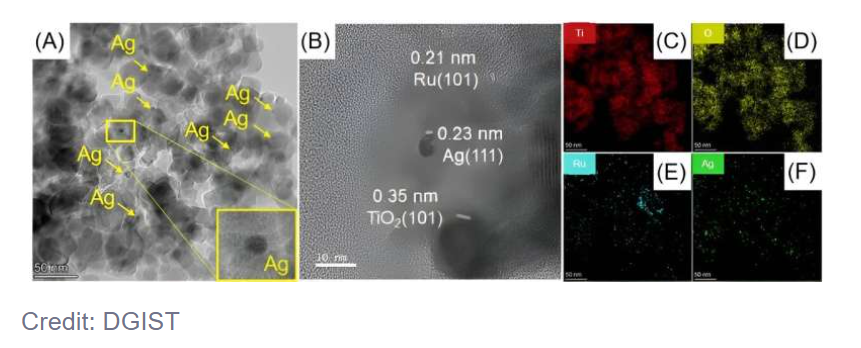

The research team at DGIST led by Professor In Soo-Il developed a high-efficiency photocatalyst by attaching silver nanoparticle co-catalysts to P25 made of titanium dioxide, and improving charge transfer performance with ruthenium doping. They also resolved the issue of a low CO2 concentration on the catalyst surface during gas-phase reactions by forming hydroxy groups on the surface of the photocatalyst through hydrogen peroxide treatment.

The research team demonstrated that electrons accumulate in an intermediate state of the P25 band structure through ruthenium doping. These accumulated electrons are then transferred to the silver nanoparticle co-catalyst, converting CO2 into methane.

The team also identified the optimal composition to efficiently produce methane from CO2 by analyzing the silver nanoparticle co-catalyst and ruthenium doping. Furthermore, by measuring the amount of adsorbed CO2, they proved that the photocatalyst surface adsorbed more acidic CO2 when it was alkalized with hydrogen peroxide.

Professor In Soo-Il from DGIST stated, “The newly developed photocatalyst improves visible light absorption, CO2 adsorption, and electron transfer capabilities simultaneously. It converts 135 times more methane with 95% selectivity compared to the currently commercialized P25 photocatalysts and maintains over 96% stability even after 24 hours of continuous operation. We will conduct follow-up research to improve the stability and selectivity of hydrocarbons for the practical application of this technology.”

The results of this research were published in Carbon Energy.

Article Credits: Tech Xplore